Welcome to

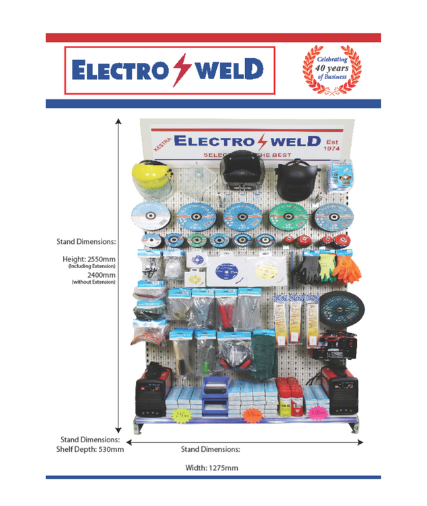

Malahide, Dublin’s Largest Suppliers of Welding Consumables

ELECTRO WELD

Industries We Serve

Electro Weld Product Range

About Us

TAKE THE FIRST STEP.

WE WILL DO THE REST.

Welcome to Electro Weld, your trusted partner in field of welding consumables. Established for over 45 years. Besides the covered electrodes and solid wires for GMAW and GTAW welding, Electro Weld also produces a wide range of flux cored wires for joining of low alloy and stainless steels, as well as applications of hardfacing for all industries. Customer satisfaction is the highest priority for Electro Weld and this is the principal reason for its continuing success. Electro Weld has a highly qualified, professional, efficient Technical Department at the disposal of its customers, offering the best solutions for your welding needs.

Reviews

KESTRA is proud to be a leader in the competitive field of welding consumables

Established for over 50 years

Latest News & Offers

GMAW Solid Wires and FCAW Tubular Wires

There are many different welding processes and wires and it can be difficult to choose which will best suit your application. Let’s examine the differences between the GMAW solid wire and FCAW flux cored wire welding processes. These processes are very popular and have some similarities, but also some very big differences. To determine which process to use, it is necessary to check some important variables. Some of the variables

Advantages of Tubular Wires Over Coated Electrodes

One of the trends in welding is the reduction of operating costs, using more economical welding processes, which have higher deposition rates. GTAW (TIG) welding provides the highest quality welds, but the method is relatively slow. For this reason, it is used most often for root passes. The rest of the joint is welded with a more efficient method, such as coated electrodes or GMAW (MIG) wires. Covered electrodes are

Tips to Avoid Common Problems and Improve Welds with Tubular Wires

Cored wire welding offers many advantages in welding construction applications, including high deposition speeds and good chemical and mechanical properties. Arc welding with self-shielded flux cored wires has been a viable welding process for assembling steel structures, heavy equipment repairs, bridge construction and similar applications for many years. This is not surprising, as this welding offers high deposition speeds, excellent chemical and mechanical properties and the weldability required for these